We can design a huge range of mechanical parts and assemblies from complex CNC machinings, injection mouldings, fabrications, additive parts (be it sintered or grown).

As well as looking after the mechanical design, our industry experts consider future volume production too; how to make your product in volume and what it will take to manufacture, all this from the first day they work on your design.

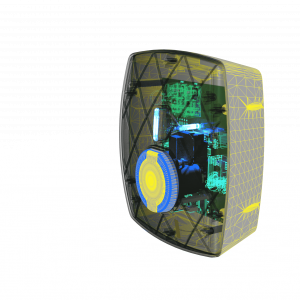

There is a key symbiotic relationship between the design of the electrical & electronic elements of a product and the industrial design / enclosure developments. The ideal timing is to have a scheme for the enclosure and a reasonable view on the features you want from the electronics. With neither element entirely frozen it maximises the likelihood of a compromise and optimisation for both disciplines which is at the heart of every great electronic product ever designed.